FAM Centris 315

Detailní popis

Machine description:

FAM has developed the innovative Centris™ 315, a new centrifugal slicer & shredder with a high-quality execution at a very attractive price and with the smallest footprint of any industrial centrifugal shredder in the market.

The FAM Centris 315™ is designed for companies looking for perfect cut quality, long shelf-life, flexibility and speed while minimizing costs and decreasing the amount of time to complete each job.

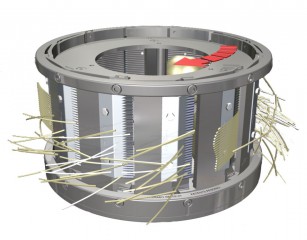

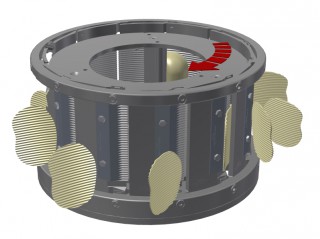

The patent pending cutting head technology (*) guarantees a consistent slice and shred thickness throughout the slicing process. Its unique design considerably facilitates the changing of blades, handling and cleaning.

(*) patent pending impeller and patent pending cutting head assembly

Capacity: up to 1.500 kg per hour depending on product, cut size and condition

Max. product diameter: 95 mm

Main features:

- Electrical control of the machine is start-stop without programming or read-outs in order to meet simplicity.

- The 100% stainless steel cutting head weighs 8 kg and has a reduced amount of parts, which improves cleanability and simplifies assembly considerably.

- Heavy-duty cassette style spindle, easily removable for inspection. Lifetime greased and sealed roller bearings.

- Rigid, seamless welded frame with no flat surfaces. Limited number of bolts used and no exposed threads.

- Large infeed provides uniform product flow to the cutting head and avoids overloading of the head.

- Equipped with a 0.75 kW AC three-phase stainless steel motor for low energy consumption and designed for easy wash-down.

- Safety closing system is preventing access to the cutting section during engine operation

- Easy operation and maintenance of the machine

Cutting principles:

The product is fed through the infeed chute and enters into the cutting compartments of the rotating impeller (*). There, it is held against the inner surface of the cutting head assembly (*) by centrifugal force.

The cutting head assembly (*) consists of 12 individual stationary cutting stations. Slices or shreds are produced as product passes each knife in a smooth and uninterrupted manner. Length is controlled by the input product size. The cut product is collected through the central discharge.

The interchangeable cutting heads (*) offer flexibility in all cuts and shapes, such as flat, crinkle cut and V-shaped slices as well as V-shaped, oval, julienne and wide ribbon-cut strips, and this on a variety of products.

(*) patent pending impeller and patent pending cutting head assembly

Cut shapes: Flat cut, crinkle cut, V-cut slices, V-cut shreds, julienne shreds and oval cut shreds

Cut sizes:

- Slices from 0.8 mm up to 5 mm,

- V-cut shreds 318V (1.6 mm), 432V (2.5 mm) and 538V (3.2 mm)

- Julienne shreds 2.4 mm, 4.8 mm, 9.6 mm, 19.05 mm

Technická data

| Power in kW | 0,75 kW |

| Dimensions basic machine (LxWxH) | 1.050 x 750 x 1.500 mm |

| Machine infeed height | 1.250mm |

| Machine outlet height | 540 mm |

| Weight basic machine | 129 kg |

Aplikace

Various kinds of fruit and vegetable suitable for slicing or shredding.