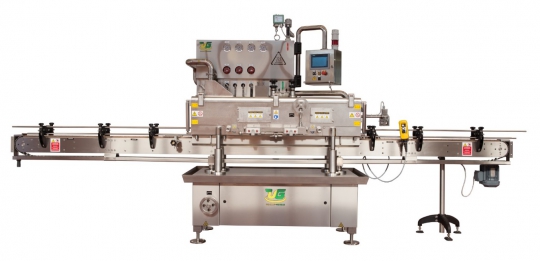

Linear capping machine GG400

The automatic linear capping machine GG400, manufactured in stainless steel, is suitable to close jars and/or bottles with metal caps type: Regular, Medium, Deep Twist-Off, Pry-Twist, Pry-Off.

The capping machine is supplied with the magnetic cap feeder at floor level GG900, which can be installed at a distance to reduce noise significantly.

Charakteristika

Detailní popis

Machine description:

Capping operation executed in a saturated steam chamber with high vacuum in the container. And with constant vacuum value. Equipped with the suitable optional sets of change parts,

The basic machine is composed of:

- Stainless steel lower base-plate with adjustable supporting feet to the floor, upper head completely made of stainless steel

- Stainless steel collecting tank under the working area

- Stainless steel telescopic columns with height adjustment by hand wheel

- Cap descent unit with centralized adjustment and pre-heating by steam

- Cap slip-off unit

- Steam distribution unit

- Motorized screwing unit for cap closing by suitable screwing and/or pressure belts

- Belt lubrication unit

- Brackets unit for container tightening and centering

- 5.000mm-long stainless steel motorized conveyor belt. Direct transfer at infeed and outfeed with contact between the chains.

- Photocell at outfeed in case of container jam

- Counter of total pieces produced and total hours worked

- Solenoid valve for steam interception

- Motorized head height adjustment to handle containers with different heights

- Steam exhauster kit with flow adjustment valves (0.25 kW)

- Centering device for the perfect centering of containers at infeed at high speed

- Programmable machine stop in case of cap absence on the container with acoustic alarm

- Stainless steel electric control cabinet with low tension controls and PLC, keyboard on the machine with touch-screen display

Capacity: Max. speed 48.000 cph with RTO Ø 38mm cap size

Advantages:

- Stainless steel construction

- High hygiene and sanitation

- Easy adjustment to different sizes with no need of special change parts,even with the machine in production

- Constant screwing strength in any working conditions

- Quick format change-over

- High resistance to corrosion

- Easy cleaning and maintenance.

Options:

- Kit for jars with height below 50mm

- Steam super heater for products like mayonnaise ancd cheese

- Extension of the conveyor (1000mm max.)

Technická data

| Motorization | 3,7 kW |

| Steam consumption | 115 kg/hour. at 3 bar |

| Air consumption | 5 Nl/1‘‘ at machine start – 6 bar |

| Water consumption | 30 l/hour. at 2 bar 5 – 15°C |

| Overall dimensions | 5.000 x 1.300 x H 2.350mm |

| Weight | 900 kg (without feeder) |

This technical sheet gives an approximate description of the machine. The technical features and the machine configuration are to be confirmed at the time of order.

Aplikace

| caps | diameter from 27 to 110 mm |

|

height from 5 to 19 mm |

|

| containers | diameter from 30 to 160 mm |

| height from 50 to 260 mm |