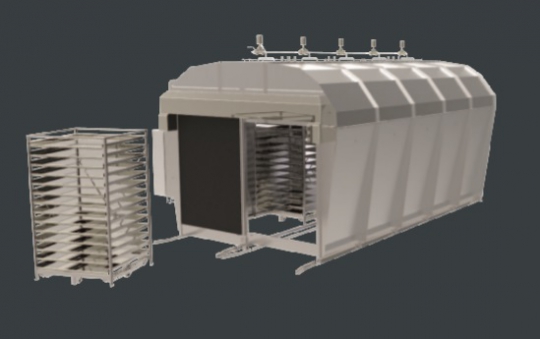

Thawing chamber

The advanced fully automatic Cabinplant thawing equipment controls temperature throughout the entire defrosting process. It keeps the product fresh.

Charakteristika

Výrobce stroje

Roesbjergvej 9

DK-5683 Haarby

Denmark

tel.:+45 40752276

PGR@cabinplant.com

www.cabinplant.com

Detailní popis

Machine description:

The advanced fully automatic Cabinplant thawing equipment is an essential part of any processing line. The trolleys with the frozen product blocks are placed in the chamber. The doors are closed and a thawing program is chosen. Via baffle plates, motorised fans direct a heated air flow into the chamber. The air flow circulates between all trolley shelves, thus ensuring even and uniform product thawing. One pair of counter-pitch fans per module ensures maximum air flow to each pair of trolleys, regardless of direction.

In order to prevent product dehydration, the air is kept humidified through controlled water particle injection directly into the air stream.

The product retains its quality during thawing, as the Cabinplant thawing chamber controls the temperature throughout the entire defrosting process. Multiple sizes/capacities are available, ranging from TC 2 - TC 16.

Capacity: depending on product

- TC 2: 500 – 1.600 kg/batch

- TC 4: 1.000 – 3.200 kg/batch

- TC 6 1.300 – 4.800 kg/batch

Main features:

- Higher yield due to reduced drip loss

- Minimum water consumption

- Reduced thawing time

- Improved product quality

- Better hygiene

- Product retains its quality during thawing

Technická data

| Dimensions basic machine (LxWxH) | |

| TC 2 | 1.500 x 3.500 x 4.100 mm |

| TC 4 | 2.700 x 3.500 x 4.100 mm |

| TC 6 | 3.900 x 3.500 x 4.100 mm |

Measures may vary depending on type of use.

Aplikace

- Block-frozen product, e.g.: whole fish, fish fillets, shellfish, meat, vegetables, fruit & berries

- Individually frozen (IQF), e.g.: whole fish, fish fillets, meat - large pieces