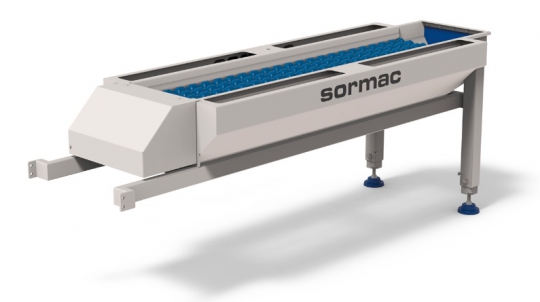

Inspection table RLT-L6/9

Detailní popis

Operating principle:

The Sormac inspection tables RLT-L6/9 consist of spiral-shaped transport rollers. These rollers are centrally driven and transport the product from the infeed point to the outfeed hopper. During transport the product rotates so that visual inspection can take place of the whole product.

By means of the simple and open construction all loose peel and other small waste can fall through the rollers on to a waste belt / crates.

Waste chutes are provided to deliver the peeling waste from inspection personnel, directly to the waste belt or crates. The inspection table RLT-L6/9 is especially suitable for onions and can be constructed directly on the Sormac onion peeler. Also a combined waste belt before the inspection table and the onion peeler can be provided.

The inspection tables can be supplied with 6 or 9 rollers and with a roller length of 2.000 mm and 3.000 mm

Features:

- Simple construction with less wearing parts

- Open construction between rollers and waste chute

- Easy to maintain

Attachments:

- Waste belt

- Control panel with frequency drive

Technická data

Aplikace

The inspection tables RLT-L6/9 are especially used for onions, but can also process other root products with a diameter of minimal 30 mm.