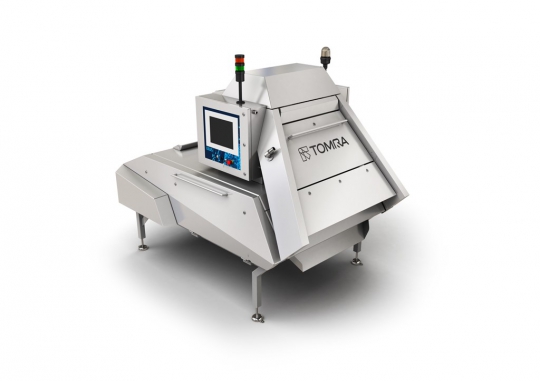

Optical sorter Ixus™ Bulk

By implementing the latest x-ray and imaging software technology, metal, stones, pits, glass, high density plastics, etc. from food is removed

Charakteristika

Detailní popis

Operating principle:

The Ixus™ Bulk x-ray sorting machine provides the safest food sorting solution for customers’ brand protection.

- X-ray detection with an unmatched resolution

- Low false reject with precise air ejectors

- Ease of use with intuitive graphical user interface (GUI)

- High capacity food sorting machine for high volume processing

Capacity: depends on the product and type of machine

Features:

SENZOR TECHNOLOGY

The Ixus™ Bulk scans products in bulk to detect foreign material that can be dangerous to your customer.

Metal, glass and small rocks (free flowing and embedded) are detected by absorbing more x-rays than the good product. The Ixus™ Bulk can also divide products into different categories such as size, shape etc.

The type of x-ray source depends on the product, type of defect and capacity.

The Ixus™ Bulk is very flexible and easy to integrate into the production line and can be used as a complementary or as a stand-alone sorting machine.

Implementing an x-ray sorting machine at the beginning of the line will decrease your incoming defect load significantly and will facilitate further processing. At the furthest end of the line, it will minimize the risk of finding anything unwanted in your final product, just prior to packaging.

PRODUCT BENEFITS

- Superior safety

- Optimized yield

- Easy to integrate

- Flexible

- Unparalleled throughput

ADVANCED SORTING CRITERIA

The Ixus™ Bulk can sort multiple food applications by the following sorting criteria:

- Foreign material

- Pit detection

Technická data

| TYPE | Ixus Bulk 420 | Ixus Bulk 570 | Ixus Bulk 800 |

| Dimensions (LxWxH) | 2.260 x 1.631 x 2.189 mm | 2.260 x 1.859 x 2.204 mm | 2.435 x 2.739 x 2.649 mm |

| Infeed belt width | 1.324 mm | 1.324 mm | 835 mm |

| Air pressure input | 6 – 7 bar | 6 – 7 bar | 6 – 7 bar |

|

Electrical consumption |

1 ph: 1,5 kVA | 1 ph: 1,5 kVA | 1 ph: 1,5 kVA |

Aplikace

Almonds, cashews, hazelnuts, peanuts, pistachios, raisins, walnuts, coffee, fresh and frozen cherries, mussel (meat) frozen and fresh, scallops, olives, whole potatoes and many others