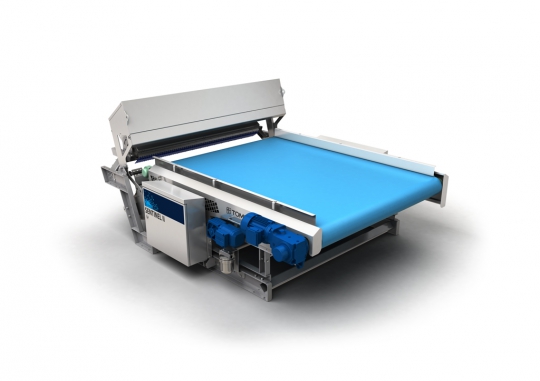

Optical sorter Sentinel II

Using the latest in illumination and detection technology Sentinel II outshines its competitors in terms of sorting efficiency, capacity, technical specification and durability. Sentinel II boosts the highest throughput to machine width ratio in the industry!

Charakteristika

Detailní popis

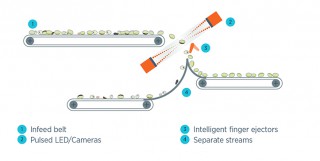

Operating principle:

The Sentinel II optical sorter is designed for sorting many food applications and will typically be found in the tomato, peach and potato processing industry.

- Highly efficient food sorting machine

- Simple to use

- Covers a wide capacity range of 40-200 tons/hour!

- Economical food sorting solution

- Open design: easy-to-clean

- Flexible sorter design, configurable to meet different sort requirements

- Double or single sided off-belt inspection of product flow for highest sort accuracy. Configurable to meet customer needs.

- Low, medium or high conveyor speed modes

- Three different size offerings: tailored to customer requirements

- Simple user interface with valuable data feedback

Capacity: 40 – 200 t / hr., depending on the application and machine configuration

Features:

SENZOR TECHNOLOGY

The Sentinel II uses TOMRA's pulsed LED/sensor arrays technology combined with a simple user interface to give our customers control over the removal of a broad range of defects, discoloration, damage, and undersize product, while also removing foreign materials such as cotton stalks, corn cobs, stones, plastic, glass, metal, wood bone and animal matter etc.

An enhanced, patented, high-speed rejection system efficiently removes defective product and foreign material, operating at higher speeds than previous models.

Sentinel II offers low, medium or high speed modes depending upon the specific application sort requirements.

With three different sorter size offerings, Sentinel II covers a wide capacity range of 40-200 tons/hour making it an ideal solution for the seasonal and year round processors seeking off-color, defect and foreign material control.

PRODUCT BENEFITS

- Attractive return on investment

- High productivity

- High efficiency

- Controllable, consistent product quality

- Yield optimization

- Stable trouble free lighting/sensors

- Simple robust design

- Reliable with low maintenance costs

- Compact footprint

ADVANCED SORTING CRITERIA

The Sentinel II can sort multiple food applications by the following sorting criteria:

- Foreign material

- Color defect

- Blemish

- Damage

- Size / form

- Subtle color

- Small defect

Technická data

| TYPE | Sentinel 1600 |

| Dimensions (LxWxH) | 2.748 x 2.465 x 1.332 mm |

| Infeed belt width | 1.600 mm |

| Air pressure input | 7 bar |

| Electrical consumption | 3 ph + N: 2,0 kVA |

Aplikace

Tomatoes (cannery), peaches (cannery), peeled potatoes, washed potatoes and many more