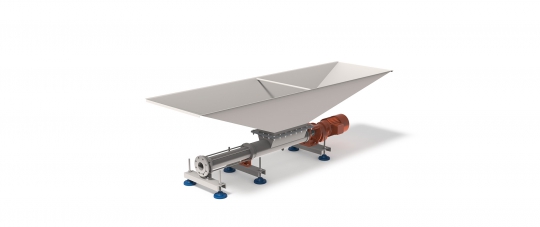

Excenter waste pump

The excenter waste pump is suitable for processing peeling waste of products like potatoes, carrots, and celeriac.

Charakteristika

Výrobce stroje

Huiskensstraat 68

5916 PN Venlo

the Netherlands

tel.:+ 31 6 30 26 96 62

i.goossen@sormac.nl

www.sormac.nl

Detailní popis

Operating principle:

The excenter waste pump is the ideal system to collect all peeled and process waste, so that it can be centralized and pumped to a central collecting area.

The Sormac excenter waste pump has the option of being combined with a collecting hopper and filling control switch. The pump is direct drive by a motor gearbox. Peeled process waste is directed into the fishtail shaped hopper or combined from additional process areas. This waste should be screened to less than 30 mm otherwise it is necessary to provide a macerator.

The standard Sormac excenter pumps are specified for an outlet pump distance of 20 meters and a discharge height of 5 meters. Alternative pumps are available depending on waste discharge volume.

Capacity: The capacity is max. 5 m³/h, bigger pumps can be delivered on request. The capacity has to fit to the expected waste flow. The quantity water should be taken into consideration which is eventually required with peeling.

Scope of supply:

- excenter pump

- motor with reductor and coupling

- dry-running protection (NTC-sensor)

- adjustable legs

Options:

- shredder for making smaller pieces bigger than 30 mm

- collection hopper

Technická data

| Pump EAP |

Pump EAP with shredder |

|||

| Type | EAP-5/12 | EAP-17/12 | EAP-10/12 - S | EAP-17/12 - S |

| Motor | 1,5 kW | 3 kW | 4 kW | 5,5 kW |

| Capacity (max.) | ±1,2 m³/hod. | ±5 m³/hod. | ±1,2 m³/hod. | ±5 m³/hod. |

| Number of resolutions | 107/ min | 130/ min | 65/ min | 130/ min |

| Press connection | DN 65 / PN 16 | DN 100 / PN 16 | DN 80 / PN 16 | DN 100 / PN 16 |

| Material (in contact with product) | AISI 304 /NBR-Perbunan | AISI 304 /NBR-Perbunan | AISI 304 /NBR-Perbunan | AISI 304 /NBR-Perbunan |

Aplikace

The excenter waste pump is suitable for processing peeling waste etc. of products like potatoes, carrots, and celeriac. Pieces of these products can also be processed if they are smaller than 30 mm. For larger pieces, e.g. whole potatoes, the pump must be equipped with an optional shredder.