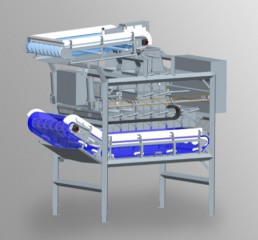

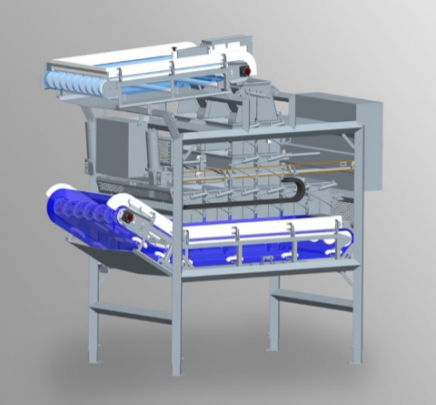

Multi batcher

The Cabinplant fully automatic multi batcher performs accurate combinatorial weighing at high speed and can handle large portion sizes.

Charakteristika

Výrobce stroje

Roesbjergvej 9

DK-5683 Haarby

Denmark

tel.:+45 40752276

PGR@cabinplant.com

www.cabinplant.com

Detailní popis

Machine description:

Cabinplant’s multi batcher is the first batcher based on combinatorial weighing. Compared to other conventional batch systems, our fully automatic multi batcher performs accurate combinatorial weighing at high speed and can handle large portion sizes e.g. whole pelagic fish. Cabinplant’s multi batcher automatically weighs raw material into sub-weights, which are then combinatorily selected to create the optimum batch weight. The principle of combinatorial weighing known from our successful screw feeding multihead weigher results in higher accuracy.

Our multi batcher is available either as a stand-alone unit for automatic or manual bagging, boxes or thermoformed packages, or as part of a complete packing line. Tailor-made according to product size and batch size as per customer’s request.

Capacity: Capacity: Up to 20 batches/ min. depending on batch size, batch size: 2-30 kg

Main features:

- Accurate combinatorial weighing at high speed

- Reduced give-away (5 times less than conventional batch systems)

- Easy to clean - easy to operate

- Constructed in AISI 304 stainless steel

- Control of equipment from PLC, recipe control

- Data collection and statistics

Technická data

| Type | MB 10 | MB 30 |

| Batch size | 2-10 kg | 4 - 30 kg |

| Hopper volume | 10 liters | 20 liters |

| Max piece size | 100-350 mm | 350 - 500 mm |

| Throughput | up to 20 batches/min. | up to 12 batches/min. |

Aplikace

Poultry (bone-in or boneless), meat (pork, beef), fresh or frozen pelagic fish